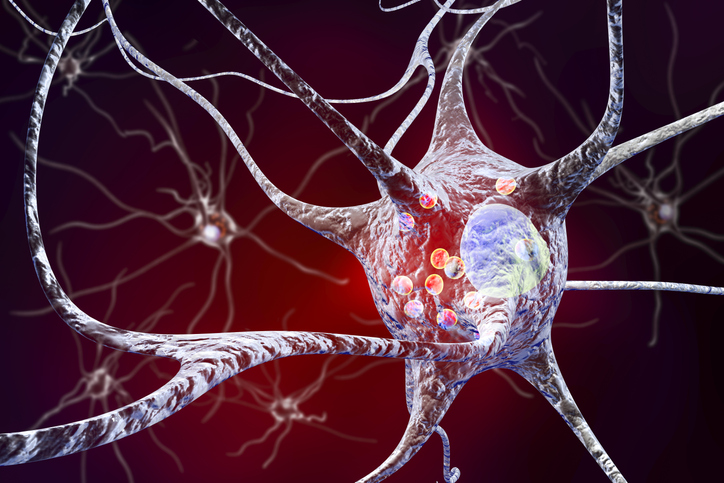

Three dimensional printing technology has been popping up in so many places, from drug development to artificial organs of the future. A pharmaceutical startup has raised $4 million, according to documents filed with the Securities and Exchange Commission, to advance the its 3D printer technology for a more efficient way to distribute medication in the body.

Aprecia Pharmaceuticals in Langhorne, Pennsylvania uses the 3D technology developed at MIT for its zip dose drug delivery system. Using a 3D printer, it produces oral wafers, which can be dispersed in less than five seconds and deliver a dosage loading of more than 50 mg, according to Ben Franklin Technology Partners of Southeastern Pennsylvania’s website. It also offers a “nano dose” that the company claims is a low dosage drug delivery with precision and accuracy. It also has biodegradable implants, according to its website.

Last year, Aprecia raised $25.7 million.

It’s estimated that the drug delivery market will rise to $199 billion by 2016 according to GBI Research, as patent losses spur pharmaceutical companies to position and reformulate their drugs. The growth in varieties of controlled release drugs and nanotechnology has also shaped the options these companies can choose from. Among some of the emerging drug delivery options are nanotechnology and orodispersible technology in which the medicine dissolves when it gets into contact with saliva for children and older patients who may have problems swallowing.