A Michigan startup is using 3D printing technology to help surgeons reconstruct skeletal defects – minimizing the need for bone grafts to fill areas with significant missing bone.

Tissue Regeneration Systems is developing porous, bioresorbable scaffolding that can replace itself with natural bone, leaving no residual implanted device. Instead of requiring metal plates and screws, the material is computer modeled based on CT scan input so that the implants fit a patient’s exact needs, CEO Jim Fitzsimmons said.

The company just raised $2 million from existing investors, which include Venture Investors, the University of Michigan, the Michigan Economic Development Corporation and Wisconsin Alumni Research Foundation.

Rather than repairing simple fractures, the startup’s platform is most useful in cases of trauma and cancer where bone tumors are removed – cases that require complex skeletal reconstruction.

“For these kinds of clinical cases, surgeons have to remove bone from somewhere else in the body – the fibula, the scapula or part of the hip – and use that to do the reconstruction,” Fitzsimmons said. “Our technology lets them do that without the need to remove the bone from somewhere else.”

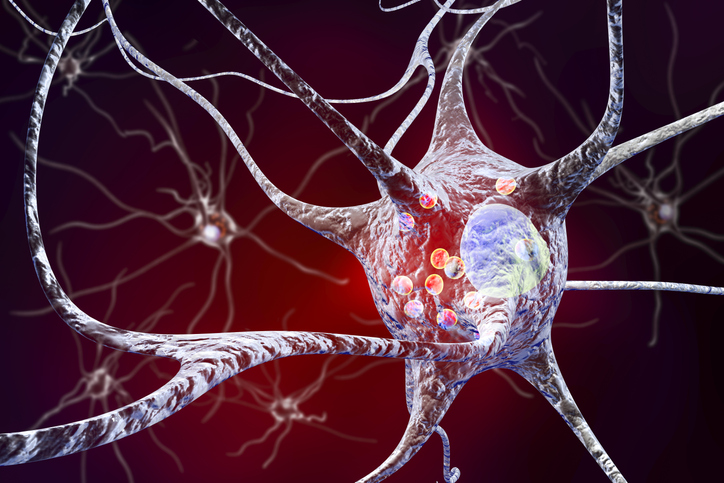

The startup’s skeletal reconstruction and bone regeneration platform has been licensed from the Universities of Michigan and Wisconsin. It last year received 510(k) approval from the Food and Drug Administration for its product that can repair neurosurgical burr holes.

The company’s got a coating technology that helps it integrate the implants with an “osteoconductive mineral coating” that it says enhances bone regeneration and proliferation into and throughout the porous implant. Orthobiologics and bone-growing stem cells can bind easily to the coating, the company said, “which allows for a controlled and sustained biologic release to accelerate new bone formation.”