L-R: Celgene EVP global pharmaceutical development Joanne Beck; Carisma Therapeutics CEO Steven Kelly; Autolus Therapeutics COO Christopher Vann; Iovance Biotherapeutics Maria Fardis; GE Healthcare Life Sciences general manager for cell therapy growth strategies Phil Vanek (panel moderator)

To date, the conversation around CAR-T cell therapies in cancers has focused on the most visible considerations: efficacy, toxicity and cost. But while those factors are important, another one deserves equal consideration: manufacturing.

Or more specifically, it’s crucial that companies making CAR-Ts ensure that manufacturing is as seamless and rapid as possible for patients who desperately need them. Companies that have been on the market for a while – Novartis, with Kymriah (tisagenlecleucel) and Gilead Sciences, with Yescarta (axicabtagene ciloleucel) – have had lots of time to gain valuable insight into the art and science of CAR-T manufacturing. But there are also countless newer players just getting their feet wet. It’s crucial that they ensure they can avoid significant manufacturing hurdles that could threaten not only their bottom lines and development plans, but patients’ lives.

Nearly a year and a half after the first CAR-T received Food and Drug Administration approval, manufacturing remains a topic of discussion in the industry, according to a panel discussion during last week’s Biotech Showcase conference in San Francisco, which coincided with the J.P. Morgan Healthcare Conference. The panel brought together executives from several CAR-T developers, including those developing therapies for solid tumors.

“It came as a surprise that manufacturing could play such an important role in a therapy,” said Celgene executive vice president for global pharmaceutical development Joanne Beck. Indeed, while the success of CAR-Ts has been “amazing,” companies went to market quickly based on manufacturing that had largely taken place in an academic setting, said Autolus COO Christopher Vann. “They didn’t have capacity like codes and procedures to support the development of these medicines,” he said.

What came as a surprise to me is that industry stakeholders are still talking about manufacturing hurdles. That’s because it’s a concern I was hearing clinical trial investigators bring up repeatedly well before any CAR-T became commercially available.

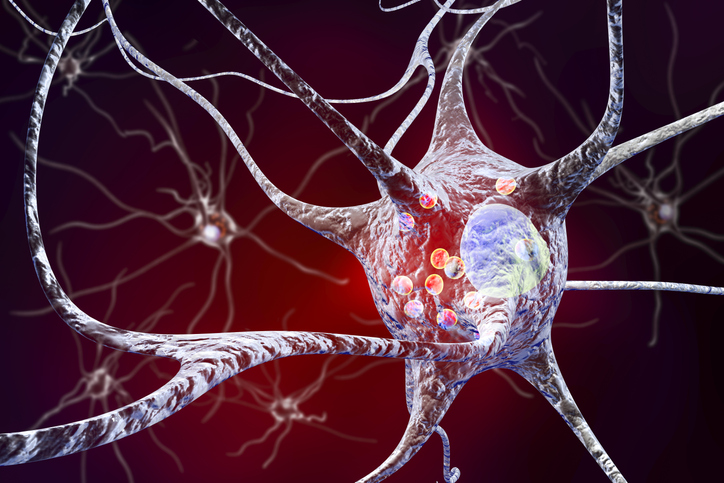

Kymriah (tisagenlecleucel) received Food and Drug Administration approval in August 2017 for acute lymphoblastic leukemia, followed by Yescarta (axicabtagene ciloleucel) from Kite Pharma – which Gilead bought later that year for $11.9 billion – for diffuse large B-cell lymphoma in adults. Kymriah was itself approved for DLBCL last spring. Juno Therapeutics – now owned by Celgene – has a CAR-T, lisocabtagene maraleucel, in registration-directed development for DLBCL, while Celgene is partnered with bluebird bio on bb2121, for multiple myeloma.

A Deep-dive Into Specialty Pharma

A specialty drug is a class of prescription medications used to treat complex, chronic or rare medical conditions. Although this classification was originally intended to define the treatment of rare, also termed “orphan” diseases, affecting fewer than 200,000 people in the US, more recently, specialty drugs have emerged as the cornerstone of treatment for chronic and complex diseases such as cancer, autoimmune conditions, diabetes, hepatitis C, and HIV/AIDS.

I started hearing about manufacturing issues with CAR-Ts when I was covering hematology-oncology drug development at BioPharm Insight, especially when I attended the American Society of Hematology’s annual meeting in December 2016. At the time, I learned from a source that the Phase II JULIET study of Kymriah in DLBCL had to be temporarily halted for enrollment because of a large backlog of patients waiting to enter and receive treatment. The holdup was in part because of the company’s decision to shift its focus from DLBCL to pediatric ALL, while hype around the therapy led to large numbers of patients being enrolled, thereby challenging the ability to keep up with manufacturing. Between Novartis, Kite and Juno, Kite had the best performance, with a waiting time of two to three weeks, the source told me.

The secret to Kite’s success was that it invested early on in manufacturing, building a factory near Los Angeles International Airport designed to manufacture CAR-Ts and other cell therapies at scale and ship them rapidly.

But a mismatch between supply and demand is already becoming an issue with CAR-Ts for solid tumors. Competition is heating up and making it challenging to enroll patients, and there are more patients waiting to be enrolled than there are clinical trial slots available, Iovance Biotherapeutics CEO Maria Fardis said in the panel, citing comments from physicians at last year’s American Society of Clinical Oncology meeting.

After ASH 2016, issues soon appeared. In summer 2017, I reported in BioPharm Insight, a manufacturing hiccup in Europe forced a JULIET site there to have the CAR-T manufactured in Novartis’s US facility, which lengthened the amount of time between apheresis and infusion – something that could be a potential problem for patients with an aggressive disease like DLBCL. Later that year, an unnamed CAR-T company had a near disaster in Boston when two patients’ doses were mixed up because they had the same initials, and they nearly received each other’s personalized, engineered T cells. I shudder to think what would have happened if either patient had received the other’s dose, but experts told me at the time that it spoke to the need for proper chain of custody when one center is dealing with multiple, competing CAR-T therapies from different manufacturers.

Considering the pace of CAR-Ts’ development – they were still little more than academic exercises as recently as 2014 – all of the issues I just listed happened a long time ago, and two of them were obviously isolated incidents. Moreover, it’s clear that Novartis, Gilead and also companies like Celgene have learned a lot since the early days. However, what continues to set autologous CAR-Ts apart from off-the-shelf pharmaceuticals and biologics is the amount of precision that must go into their manufacturing. Time is of the essence, and a significant wait can be a matter of life and death for a patient with a fast-growing or heavily pretreated cancer.

Consequently, it’s crucial that any company developing CAR-Ts figure out manufacturing and ensure that patients receive their therapy in a timely fashion. Doing so is every bit as important as determining safety, safety and proper reimbursement mechanisms.