Talk to enough biotech industry folks and the phrase “the product is the process” is bound to come up. It refers to cell therapies, which are made by engineering human cells. In short, the medicine is an extension of the process that produced it. Today, that process is time consuming, mostly manual, and very expensive.

NEMT Partner Guide: Why Payers and Providers Should Choose MediDrive’s TMS

Alan Murray on improving access for medical transportation.

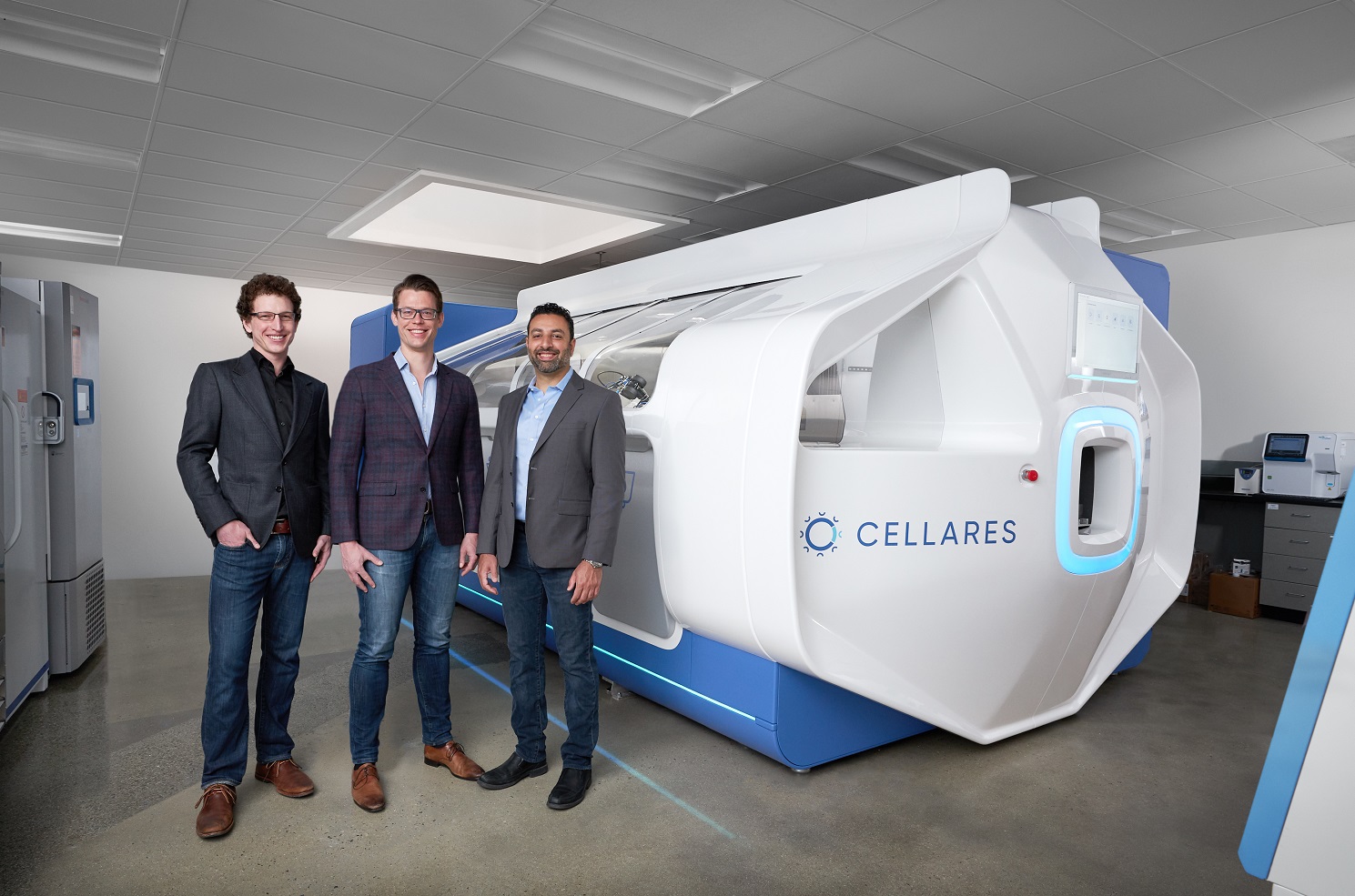

Cellares aims to do for cell therapy production what the assembly line did for automobile manufacturing. The startup is developing an enclosed system that makes the production process automated and scalable. Cellares already has prototypes of the system, called Cell Shuttle, in place with life science industry partners that are testing it. On Wednesday, the South San Francisco-based company announced an $82 million Series B round of funding to ramp up development of its technology.

Cell therapies present a whole set of challenges that just don’t exist for other types of medicines. Small molecule drugs are made in manufacturing plants that can scale pill production to the tens of thousands. That’s harder to do for biologic drugs, and it’s impossible for making a cell therapy that starts by harvesting a patient’s immune cells from a vein.

For the type of immunotherapy called CAR T, harvested T cells are transported to a lab where they are engineered to recognize a patient’s cancer. Those cells are multiplied in a lab at a different location, then sent back to the clinical site, where they are infused into the patient. Each step of the process is largely manual, and humans can make mistakes, Cellares co-founder and CEO Fabian Gerlinghaus said in an interview late last year. The length of this process, which the industry calls “vein-to-vein time,” can take several weeks.

“The problem of how do we manufacture cells at commercial scale really only exists since 2017,” Gerlinghaus said, referring to the year the FDA approved CAR T products from Novartis and Gilead Sciences. “It’s a fairly new problem. Prior to that, cell therapy development was largely in the clinic and the preclinical phase.”

Gerlinghaus described Cell Shuttle as a “factory in a box.” The system is entirely enclosed, serving as its own clean room. It also houses all the instruments, some of them robotic, for processing the cells. Cell Shuttle can process up to 10 therapies at once—that’s 10 therapies for 10 different patients. In preclinical research, that capability can be used to conduct different experiments in parallel, Gerlinghaus said. And that vein-to-vein time? Depending on the cell therapy, Cell Shuttle can cut that time down to one or two days, Gerlinghaus said.

The idea for Cellares came to Gerlinghaus in pre-pandemic times, while he was chief innovation officer at Synthego. At in-person industry conferences (remember those?), he heard about the progress of cell therapies. He also heard about the problems. Cell therapy developers talked about the challenges of manufacturing these therapies at scale.

Gerlinghaus teamed up with two other Synthego veterans, Omar Kurdi and Alex Pesch, to co-found Cellares in 2019. The startup raised an $18 million Series A round of funding led by Eclipse Ventures but kept mostly quiet about its work until late last year, when it started to test its technology with industry players. The Fred Hutchinson Cancer Research Center was announced as the first research partner last October. The center gains early access to Cell Shuttle while Cellares gets insight about how the technology fits into manufacturing workflows. Earlier this year, PACT Pharma of South San Francisco was the first company to enter this partnership program.

Cell Shuttle could make cell therapies more accessible and more affordable for more people. In addition to speeding up the manufacturing process, Cellares claims its technology lowers manufacturing costs by 75%. Gerlinghaus envisions Cell Shuttle being marketed to three segments of the life sciences industry. The first is pharmaceutical companies, large ones as well as startups. Cancer centers and hospitals represent the next target customer group, followed by contract development and manufacturing organizations (CDMOs).

Cellares has competition in the effort to automate cell therapy manufacturing. Ori Biotech is developing an enclosed and automated cell and gene therapy manufacturing system. The London-based startup closed a $30 million Series A financing last October. Lonza is developing technology that performs the manufacturing steps in a disposable cassette loaded into a system it calls Cocoon. The Cocoon technology comes from Octane Biotech, a startup based in Canada and a Lonza partner. In 2018, the CDMO giant paid an undisclosed amount to acquire an 80% ownership stake in Octane. The deal also gave Lonza the right to acquire full ownership of the startup.

The latest Cellares financing was co-led by Decheng Capital and Eclipse Ventures. Also participating in the Series B round were 8VC and Skyviews Life Sciences. 8VC is a returning investor to Cellares while Decheng and Skyviews are new ones.

Photo by Cellares