With the medical supply chain shifting to high gear, delivering millions of Covid-19 vaccines to an anxious and eager population, it’s easy to miss the long-term challenge brewing beneath the surface of the immediate rollout. First, we must recognize that the manufacture and rollout of messenger ribonucleic acid (mRNA) treatments on such a massive, industrial scale represents the biggest medical breakthrough of our lifetime. However, the ongoing response to the global pandemic has revealed serious vulnerabilities in the pharmaceutical industry’s fragmented infrastructure of cold chain storage and delivery logistics. These problems must be addressed before the next wave of mRNA medications —expected to treat cancer, heart disease, cystic fibrosis, and more — become widely available.

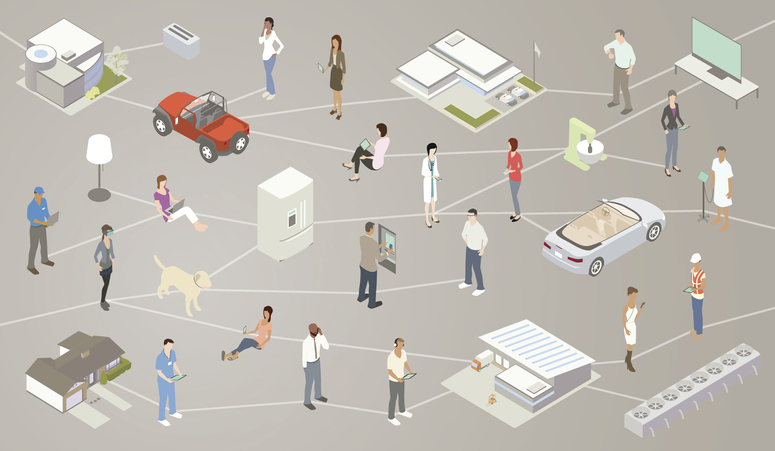

The successful integration of internet-enabled devices and sensors (also called “the internet of things” or IoT) is the crucial ingredient to realize the promise of this new class of vaccines and drug treatments. Automated, portable, and digitally connected sensors provide stakeholders with substantial “next-generation” benefits as they provide end-to-end visibility within the value chain’s ecosystem. These include monitoring real-time temperature fluctuations in equipment during shipment and storage, multiple alert options when problems arise, while also gathering data for additional analysis and recommended actions.

With the Rise of AI, What IP Disputes in Healthcare Are Likely to Emerge?

Munck Wilson Mandala Partner Greg Howison shared his perspective on some of the legal ramifications around AI, IP, connected devices and the data they generate, in response to emailed questions.

Reducing the high amount of drug delivery spoilage

Why has IoT enablement grown so important for the healthcare industry? Unlike the more familiar protein-based vaccines (such as those used to fight DTaP, polio, and most flu viruses), mRNA is a gene-based vaccine, developed within eight months after scientists mapped the genetic sequence of Coronavirus. While mRNA has been studied for decades and deployed against the Zika and Ebola viruses, its current deployment in the fight against Covid-19 has revolutionized the time required to create a specifically tailored and targeted vaccine. It is, in essence, genetic material that will be read by our living cells to produce the immune system’s proteins. Packaged up in oily bubbles of lipid nanoparticles, mRNA vaccines are fragile. They must be kept cold and inert until it’s ready to begin their work in your body.

Given the industry’s current practices, new technology investments in IoT enablement are needed to leverage this breakthrough. Indeed, pharmaceutical suppliers organized their cold chain management response for mRNA’s ultracold freezing and storage requirements. However, pre-pandemic statistics for drug spoilage by the International Air Transport Association (IATA) for all vaccine deliveries reached a whopping 25 percent. Not surprisingly, news broadcasters recently described snowbound healthcare workers frantically distributing Covid-19 vaccines on the highway to any available driver when their storage system failed or giving away end-of-day, leftover vaccines.

In these situations, the public-at-large wants this vaccine. Imagine if these responders had to find a more targeted end-user for, say, an mRNA cancer-fighting drug. One hospital executive told me that he spent weeks waking up in the middle of the night to check the temperature of his facility’s freezer units. The ultra-cold storage unit had one sensor, capable of alerting only him, protecting a $2 million, life-prolonging investment. That is not an effective, robust, or scalable way to safeguard the fragile mRNA drugs we have today — or the ones coming in the foreseeable future.

IoT’s Crucial Role in Cold Chain Management

To fight today’s pandemic, the World Health Organization recommends partnerships between government agencies, health responders, and private industry to expedite any technical or logistical barriers to a fast, effective vaccine rollout — now, or in the future. Here are several key points to consider before choosing an IoT partner:

Open Data Integration: IoT technology is not a “one-size-fits-all” solution. The equipment and machinery used for cold chain’s temperature-controlled value chain may generate thousands of actionable data points every minute. But often, installed components don’t speak to each other creating islands of closed systems. Open platforms, however, can send and receive aggregated data from disparate, disbursed systems in a timely manner. Make sure your IoT partner is leveraging open data protocols that will reduce costs and speed ROI, alleviating the need for time-consuming workarounds.

Connectivity: Without 24/7 access to the internet, stakeholders can’t be assured of real-time alerts, verified compliance, or status and location of physical assets like vaccines. Traffic jams, lack of broadband for rural deliveries, or common electrical outages can cause track and tracing outages for temperature-controlled supply chain logistics. Check that your IoT provider has a fallback plan for internet connectivity, including 4G or LTE service when Wi-Fi broadband is not available.

Data Security: Confirm that your technology partners comply with federal requirements for data security and privacy. The healthcare industry is regulated by HIPAA provisions. Information technology providers should have ISO 27001 certification for data handling and governance, whether stakeholders are deployment from a public, private, or hybrid cloud environment.

Dashboard Capabilities: Once a digitally enabled solution has been validated, be certain that key managers have the ability to view metrics, recommendations, and monitor developments from a single web-based visual interface. Make sure the system continues to be customized as business requirements change or delivery protocols evolve. IoT platforms significantly improve compliance with government regulations, reduce (or pinpoint) instances of drug theft or counterfeiting, and human error with time-stamped visual updates. But this works only if their monitoring tools are user-friendly and easily accessible.

Leveraging IoT for a holistic approach Too many cold chain suppliers are still monitoring deliveries and storage compliance with paper-based documentation by individuals scanning thermometers every two hours. Such systems fall short of 21st-Century requirements for biologic medicine.

In contrast, sophisticated IoT platforms that leverage artificial intelligence will collect and analyze a huge amount of supply chain data (far more than even the most capable people can humanly process) to seek patterns and provide valuable insights for improving operations. Benefits and savings include optimizing transportation routes, mitigating disruptions in warehouses and distribution centers, offering predictive alerts on equipment failure or needed repairs, and making other actionable recommendations on inventory management and planning.

Delivering vaccines to fight Covid-19 may be the biggest distribution challenge the healthcare industry has tackled since eradicating polio, measles, and whooping cough. But, as the political adage says, we should never let a big crisis go to waste. The partnership of IoT technology with medical innovation will open the door to a healthy future for all.

Photo: mathisworks, Getty Images

Ken Mills serves as the CEO of Epic IO Technologies, a global firm headquartered in Fort Mills, South Carolina. Previously, Mills served as the General Manager and CTO at Dell Technologies Safety & Security, IoT, and Computer Vision business unit. He is a regular contributor to the Forbes Technology Council.