Cell therapies are already here, with treatments now available for some cancers and rare diseases. But bringing such living medicines to more patients presents both scientific and financial challenges. As cell therapy research moves from rare diseases to more prevalent conditions, these treatments will cost multiple millions of dollars per dose—costs that are unsustainable for the healthcare system, said Ryan Clarke, co-founder and CEO of startup Syntax Bio.

Many research efforts are underway with the shared goal of improving the way cell therapies are manufactured. Some of them focus on automating the process with robotics and software. Others apply gene-editing technologies to cells from donors to reduce the risk of an adverse immune response. Syntax works with induced pluripotent stem cells (iPSCs), which have the ability to become almost any type of cell. The startup applies CRISPR to guide iPSCs through various steps that lead them to become a desired cell type.

“This is completely a biological problem rather than a bioreactor problem,” Clarke said.

Chicago-based Syntax launched in 2021. In the two years since, the startup has refined its technology and shown it can turn iPSCs into four different cell types. The startup was named the winner in the biopharma track at the MedCity News INVEST conference in May. It continues to make progress with its technology and is now looking to raise $20 million in Series A financing.

Syntax’s platform technology has its roots at the University of Illinois Chicago, where Clarke’s research focused on transcription factors of genes that control what a stem cell becomes. After receiving his Ph.D., he took a job doing drug discovery research at Sana Biotechnology, a company developing new cell and gene therapies. Clarke said the experience exposed him to the state of the cell therapy field and the challenges of manufacturing various cell types. But he said he found himself wanting to commercialize the technology he had invented in graduate school.

There are two ways to make cell therapies from stem cells. In directed differentiation, iPSCs are grown in media that contain growth factors that direct the stem cells to become a particular cell type. The culturing media is changed over the course of this process, which can take 50 to 100 days depending on the desired cell type. Directed differentiation can be used to make any cell, but this method is slow, expensive, and difficult to scale, Clarke said. It’s acceptable for making cells for a small Phase 1 clinical trial. Beyond that, the manufacturing need becomes enormous, he said.

Solving Healthcare’s Provider Data Problem Starts with Interoperability

Break down the silos. Take control of your provider data.

The alternative cell therapy manufacturing method is a synthetic biology approach that skips over the multiple steps of directed differentiation. Instead, transcription factors are used to turn iPSCs into the desired cell type. This method is faster, scalable, and less expensive, but it also has limitations. It only works for certain cell types, such as neurons, endothelial cells, and some liver cells. Furthermore, the intermediate steps that are skipped in favor of speed are important, according to Clarke.

Syntax designed its cell therapy technology to overcome limitations of both directed differentiation and synthetic biology. The company’s approach takes cells through the multi-step process of differentiation, more closely mimicking what happens in the body to direct iPSCs to become various cell types, Clarke said. Syntax’s process is regulated by episomal plasmids that the company calls cellular algorithms. These “Cellgorithms” (a term coined by Syntax) do not do any gene editing. Instead, they use CRISPR to turn certain genes on or off in a particular sequence in order to direct the iPSC to the final cell state. The process takes about a week. Clarke likens Syntax’s approach to a computer programmer writing a line of code to execute a task.

“We’re trying to write multiple lines of code,” he said. “CRISPR is the absolute best medium for that. Target it to any gene in genome, turn if on or off. It’s a very flexible tool to execute the programming.”

Research describing the first generation of the Cellgorithm system was published in 2021 in the journal Molecular Cell. That initial research paved the way for $9 million in seed financing, co-led by DCVC. Clarke said Syntax is now on the third generation of the technology, which is more efficient and modular. With the new round of financing that the company is raising, Clarke said Syntax aims to show that cells produced by its Cellgorithms work in lab tests. Next, the company will validate those cells in animal testing. The potential of the Syntax technology impressed the Pitch Perfect judges. Kelly Kaihara, director, life science tools and diagnostics, General Inception, called the Cellgorithm system a “paradigm-shifting moonshot method” that could revolutionize cell therapy manufacturing.

“It is exactly the type of idea and company that we are looking for,” he said. “One that makes a major technical leap forward but also provides a platform to address multiple human diseases.”

Syntax aims to take some cell therapies to human testing, potentially leading to partnerships with larger companies that can continue their clinical development, said Leo Kelly, the startup’s vice president of corporate strategy & ops. But another part of Syntax’s strategy is to work with entities throughout the cell therapy ecosystem—drugmakers that are developing cell therapies as well as contract research organizations and contract development manufacturing organizations. Kelly said Syntax can integrate its technology with that of another company, helping it manufacture cells at scale.

One of the cell types that Syntax has generated is a beta cell from the pancreas, which could become a type 1 diabetes cell therapy. Several other companies are further along with type 1 diabetes cell therapy research. Over the summer, CellTrans won the first FDA approval for a type 1 diabetes cell therapy. That Chicago company’s therapy, made from pancreatic cells sourced from deceased donors, requires chronic immunosuppression to prevent the patient’s immune system from destroying the transplanted cells. Vertex Pharmaceuticals has three type 1 diabetes programs, one of which is derived from iPSCs that are edited with CRISPR technology. Eli Lilly’s cell therapy contender also comes from iPSCs. But Kelly says that rather than being competitors, these companies could end up being Syntax customers in various therapeutic indications.

“We don’t need to beat Vertex,” he said. “We need Vertex, Lilly, and others to compete for who uses our manufacturing solution. That’s what we’re thinking about—make cells others can’t make because of the biological complexity.”

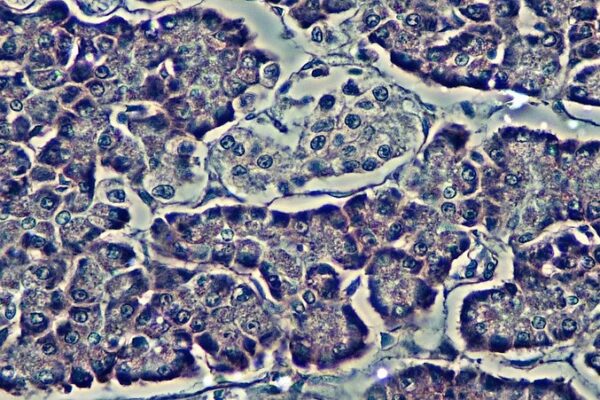

Public domain Image by Flickr user Berkshire Community College Bioscience Image Library